Planning Contract Management

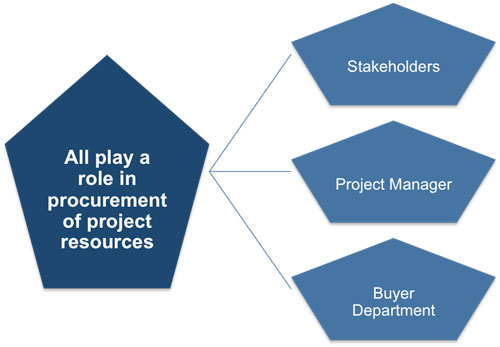

Contract management involves determining which products or services a project will need to procure from an external source and what types of contracts that need to be used on the project.

|

The decision being made here is either to 'make or buy', and the requirements of the project schedule and consideration of the resources available will both have an influence on this. Part of these decision-making processes involves the project manager liaising with the relevant stakeholders for each potential purchase.

The questions that need to be answered as part of this process include:

1) What products or services is it best to buy in?

2) How could this best be done?

3) How much is needed?

4) When does this need to be done?

This process includes consideration of the risks involved with each 'make-or-buy' decision. It also includes reviewing the type of contract planned to be used with respect to mitigating risks, sometimes transferring risks to the seller. (To learn more about understanding how to manage risks associated with a project download our free 'Project Risk Management' eBook.

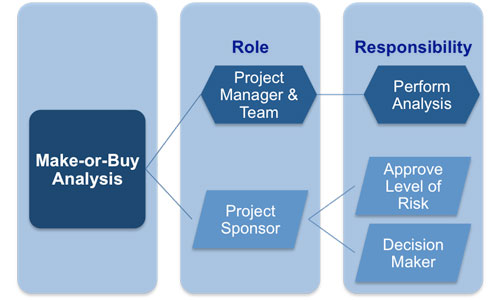

A 'make or buy' decision will need to be taken where the option exists to do the work in-house as part of the project or to purchase some products or services from outside suppliers. The most important thing to note about these decisions is that the project manager should not be the one to take them.

|

It is the project manager's responsibility (along with the project management team) to perform the analysis in each case, but the actual decision must be taken by the project sponsor and documented as such. The reason why this is so important is because of the potential risk involved in passing work to a third party over whom the project manager has no direct control. This 'make or buy' analysis weighs the many factors that could influence the decision including: cost, risk factors, in-house skills, knowledge or experience, and sharing of confidential information & other security matters.

Sometimes a capability may exist within the project organization, but may be already committed to working on other projects, in which case the project may need to outsource the work in order to meet its schedule commitments.

|

The analysis should consider all related costs; both direct costs as well as indirect support costs. For example, the buy-side of the analysis includes both the actual out-of-pocket costs to purchase the product, as well as the indirect costs of supporting the purchasing process.

The procurement plan is a part of the project plan and describes how all of the other buying-in processes are to be carried out. It describes in detail:

1) What will be procured for the project

2) Type of contract used

3) How they will be selected & managed

4) How their performance will be measured

5) How the risks associated with buying-in resources are to be managed.

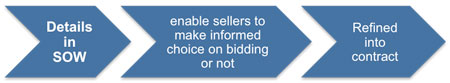

The scope of the project will have already being defined at this point in time, and this will be used to prepare procurement statements of work. Each statement of work (SOW) describes and explains the appropriate section of the project scope for use by potential sellers. It should be in sufficient detail so that such sellers can make an informed choice about whether they are able to, or want to bid for the work.

|

Sufficient detail can vary based on the nature of the item, the needs of the buyer, or the expected contract form. Information included in a SOW can include specifications, quantity desired, quality levels, performance data, period of performance, work location, and other requirements. The purchasing SOW can be revised and refined as required as it moves through the buying-in process until incorporated into a signed contract award.

Procurement documents are used to solicit proposals from prospective sellers and may include:

• Requests for Information (RFI)

• Invitations for Bids (IFB)

• Requests for Proposals (RFP)

• Requests for quotations (RFQ)

• Tender notices

• Invitations for negotiation,

• Invitations for seller's initial response.

The important thing is that these documents tell the seller exactly what is required of them. They must be detailed enough to ensure consistent, appropriate responses, but flexible enough to allow consideration of any seller suggestions for better ways to satisfy the same requirements. In addition, the complexity and level of detail should be consistent with the value of, and risks associated with, the planned procurement.

It is common practice to limit the number of suppliers invited to bid so that you have sufficient time to read and understand each suppliers offering within the assigned timescales of the project plan. Generally organizations' will only engage between three to five suppliers in more in-depth discussion and negotiation.

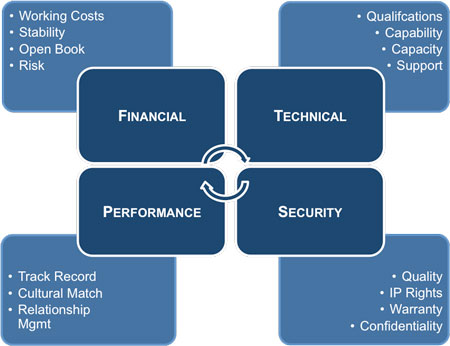

Selection criteria must be defined before the work is outsourced and fits into four broad areas - financial, technical, security and performance. Although it could be something as simple as purchase price or delivery dates if the item being procured is readily available from a range of suppliers. In more complex scenarios there are other factors that could be considered within each area.

|

Financial

It is important to know how financially stable any organization is that you are considering working with. Using the financial statements - balance sheet, cash flow analysis and income statement - will enable you to calculate the solvency, performance and profitability for each of your potential suppliers. To learn more about these financial calculations, see our free finance skills eBooks.

Many organizations now use open-book accounting when working with partners and this offers total financial disclosure between the parties. Anyone looking at these accounts would be able to discern the cost of materials and operations. It enables the project manager to make a detailed analysis of how much a working partnership would cost.

Knowing the financial capacity of your supplier helps you assess the level of risk involved in such a relationship. You can determine how financially able they are to meet the promises they have made contractually. It may mean that you stipulate the size and type of business of potential suppliers in order to reduce the level of risk associated with outsourcing the SOW and to make price comparisons.

Technical

The technical capabilities of any potential supplier are critical part of the selection process. Your short-list of suppliers (usually two or three) must be able to illustrate that they have the right level of technical competency, skills and knowledge required by the project.

This should include a thorough understanding of the methodologies that they will be use, plus an assessment of how compatible their procedures are with yours. The closer the match the lower your level of technical exposure will be.

Another aspect of technical selection criteria concerns the supplier's ability to 'make' the quantities of the product, to the required quality standard needed for the project. For some projects another the criteria supplier need to demonstrate is their technical ability to respond to potential future requirements that arise as a result of approved change requests.

Security

This area of your supplier selection is quite broad, going from physical security of the product and place of production to intellectual property (IP) rights. It is vital that you understand how much control the potential provider has over its supply chain. This may include understanding how the seller enforces s terms of the reliability and quality of the supplies it buys in for the project needs, for example, warranty coverage, quality standards, length guarantees etc.

An essential aspect of checking your potential suppliers' security is their commitment to quality.

1) How well does their product or service match up to its sales claims?

2) How do they ensure and monitor quality?

3) Do such claims match or exceed your project requirements?

4) Any provider should be able to demonstrate their adherence to a recognized quality standard, such as, IS9001, QS9000, ASTM, DIN, EN, IEC etc.

Making sure that you clearly define what exactly constitutes your intellectual property is essential. It is imperative to ask suppliers if they want to retain certain IP rights. This can be in terms of the work processes or in the services they provide as part of the project.

Performance

Any supplier you short-list must be able to demonstrate their ability to deliver their contractual obligations in their track record and by supplying references. These will give insight into how well each supplier met their contractual obligations and managed their supplier relationship (SRM) throughout the project lifecycle.

This helps the project manager assess each supplier's ability to keep to costs and schedules. It also signifies how well they managed communications giving an indication of how well the cultural fit is between your two organizations'. The actual bid a supplier submits to your organization will reflect how well they have understood the project requirements and reveal the type of relationship they want to create.

The most effective style of SRM is the collaborative approach where both sides work as one team fully sharing information. This type of relationship is not always possible due to strategic and competitive nature of many projects so a co-operative suppler relationship management style is adopted.

You may also be interested in:

Managing Project Costs | Estimating Project Costs | Calculating the Total Project Budget | Monitoring Project Expenditure | Buying-in Goods and Services | Managing Project Suppliers | Planning Contract Management | Understanding Different Contract Options | Managing Supplier Relationships.

|

|